ITALIAN PLASTICS INSTITUTE (IIP) EQUIPPED WITH A LABORATORY TRAINING LINE BY TECNOMATIC

The Istituto Italiano dei Plastici (IIP) has recently launched a detailed and ambitious network of companies (Cesap and Cerisie), with similar mission and mutually supportive strategies, with the goal of creating a Leading Center of expertise, even institutional, on the issues and the problems inherent in the plastics and polymers in general, capable of delivering a full range of services (from system certifications to those of product inspections to laboratory tests, from training to technical and technological support to the development and improvement of products and industrial processes) in prevailing system of accreditation.

Inspired by the changing needs of companies (4.0) in the era of the Fourth Industrial Revolution, a revolution that involves companies, who face the challenge of combining innovation and business, while technology is advancing very quickly and increasingly digital is creating new operational models, often imposing a review of processes and a change of paradigm, at the level of organization, of the relationship between machine and man and new skills.

Human Resources therefore become agents of change, promoters of a different way of conceiving work, also through specific training, which is essential to nurture knowledge, the development of new professional skills and human capital.

IIP decided to invest through its partner Cesap is this strategic and valuable program for the players of plastics processing sector, considering that “The ten professions today most requested by the market did not exist until 10 years ago”. The new training proposal is based on the COMPETENCE –> INNOVATION –> VALUE relationship.

The Yūshū Sentā, the Center of Excellence, is able to combine high specialized expertise of Cesap with the broadest endowment, on national territory, of process plants and test equipment of IIP for the theoretical-practical and rigorously scientific analysis of the most advanced methods of analysis and simulation about the main technical and technological processes in the polymers sector. Participants in the event were able to visit both the constantly updated IIP laboratories and the recently established OpEx ACADEMY, where courses on the main World Class Manufacturing methodologies (TPM + Lean Production + TQM), Six Sigma, of ENERGY MANAGEMENT and EFFICIENCY to finally focus on the practical demonstrations carried out at the Plastics Smart Hub 4.0 (for a total area of 1,800 square meters)

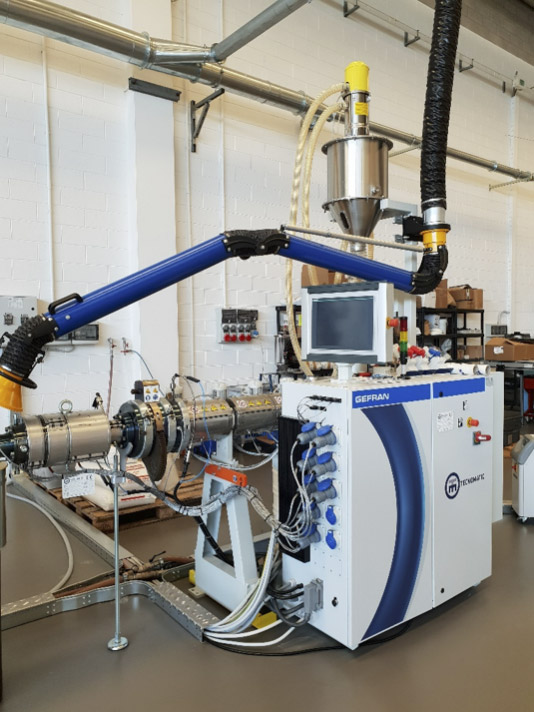

To fullfill the needs of this Center, Tecnomatic has supplied a tailor fit line with an extruder of the well tested serie ATLAS, in Ø 45 and L/D ratio 30, characterized by a special screw design able to manage different materials. The extruder and the line is controlled via the EPC (Extrusion Process Control) to centralize all parameters of the extrusion process, including the parameters of the integrated loos in weight gravimetric system. A die-head based on spiral distributor, a four meters vacuum tank, a two caterpillar haul-off and a guillotine cutter are completing the configuration of the training and testing line.

Tecnomatic is extremely proud to be a supplier of the Italian Plastic Institute and Cesap and express its gratitudine to the Managing Director Mr. Mauro La Ciacera and to the Technical Director Mr. Mario Romersi for the trust in the company equipments, as well as the companies that cooperated in it: Gefran, IPM, FB Balzanelli.