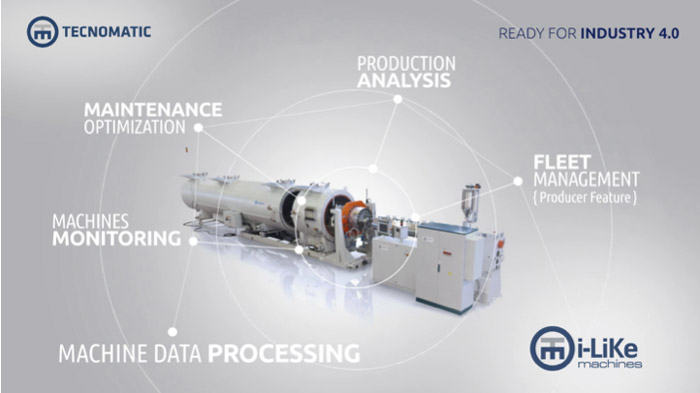

READY FOR INDUSTRY 4.0.

Industry 4.0 technologies, energy and performance efficiency to increase produtivity and to reduce risks in the pipe manufacturing process.

An innovation which will change the future and it’s already changing the present is definitely “INDUSTRY 4.0”, which is becoming increasingly important and is involving more and more factories.

Indusrty 4.0 plays a strategic role in coordinating, synchronizing and analyzing the machinery’s process,as well as supplying very important data to the human operators. Therefore the production process will be more accurate and will make the human operator work easier.

At the exhibition customers will be introduced at the system, aimed at supporting the new digital industrial revolution, providing to the plastic pipes manufacturers a complete and integrated portfolio of products, solutions, industrial software and automation technologies.

The system provides a simple userfriendly program for the networking of extrusion pipes lines. Via the machine’s EPC (Extrusion Process Control) system, several machines and peripherals are connected and linked together to be operated via a uniform user interface, which enables interaction between the individual appliances. In this way, the entire manufacturing process, including material feeding, temperature control, syncronisation is coordinated and tracked. Another important point is having all parameters centrally recorded and monitored. The system allows, not only to carry out energy monitoring, but to convert numbers and data into valuable information on the processes within the line. This enables optimal analysis of a line’s performance. From the relevant key performance indicators (KPI) for shift supervisors up to the clear presentation of the line performance for the management. Perfectly in line with the concept of “smart factory” of the Industry 4.0, all data, including preventive maintenance and service parameters or alarms can be monitored via internet or intranet, to Pc, servers or to mobile devices. Currently, Tecnomatic’s PIPE 4.0 system is the most cuttingedge software for plastic pipes extrusion.

Certain that it will be essential to better face the ongoing Fourth Industrial Revolution, Tecnomatic has already made it available on the market. Positive customer feedback relating to improved plastic pipes extrusion, due to better monitoring and management, is what gives Tecnomatic the certainty that it is heading in the right direction.

The investment on Industry 4.0 brings about many advantages as:

– Predictive lines management: maximize lines utilization and minimize unplanned downtime. Optimization of planning and scheduling of maintenance activities. 1. Reduction of failures and downtime. 2. The prediction model generates alerts and recommendations

– Process management and control: minimize production variability and improve quality, e.g. addressing production on the most efficient lines according to the kind of pipe.

– Energy management: Reduce energy costs through energy monitoring for line and process.

– Production analysis: monitor lines, processes, people and products on a continuous real-time basis. Display KPI’s (key Performance Indicators) and usage reports.

– Production simulation: manufacturing and down-time planning, costs forecasts.

– Safety management: connected technologies can help companies in continuously monitoring and recording products and quality for each produced lot, as well any generated waste (records of dimensional changes, temperature instability, breakdowns)

– Production forecasting: adjust production schedules in line with changing customer needs, raw material availability.