REVOLUTIONIZING FIBER OPTIC INFRASTRUCTURE: THE RISE OF MICRODUCT PIPES AND TECNOMATIC’S OUTPERFORMING DIE-HEAD AND LINE.

In the era of rapid technological advancement, where connectivity is king, the demand for high-speed internet has never been greater. With this surge in demand comes the need for robust and efficient infrastructure to support it. Enter microduct pipes for optical fiber, a groundbreaking solution that is revolutionizing the telecommunications industry.

Microduct pipes are small, flexible conduits designed to house optical fibers, protecting them from environmental factors while facilitating easy installation and maintenance. Their compact size and flexibility make them ideal for various applications, from urban environments to rural areas, and even within buildings.

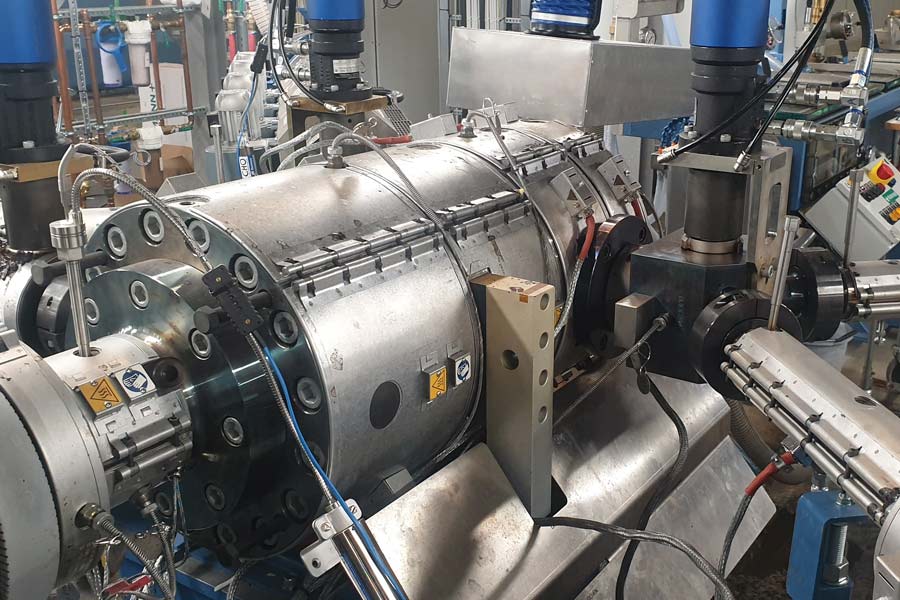

One of the key players in this burgeoning market is Tecnomatic, a company at the forefront of innovation in extrusion technology. Tecnomatic’s groundbreaking lines, specifically engineered for microduct pipe production, have set new standards in terms of speed, efficiency, and quality.

At the heart of Tecnomatic’s innovation lies its die-head, meticulously designed to achieve unprecedented production speeds. Capable of reaching up to 400 meters per minute for diameters of 7/3.5 and up to 200 meters per minute for diameters of 14/10, this die-head stands as a milestone in microduct pipe manufacturing.

The secret behind Tecnomatic’s remarkable speed and precision lies in its innovative geometries, precise line adjustments, and profound understanding of the production process. By optimizing these factors, Tecnomatic has been able to push the boundaries of what was once thought possible, achieving production speeds that were previously unimaginable.

One of the most remarkable achievements of Tecnomatic’s die-head is its ability to maintain impeccable sizing results even at such high speeds. With minimal tolerance and ovality, the microduct pipes produced are of the highest quality, meeting the stringent standards of the telecommunications industry.

Moreover, Tecnomatic’s die-head is engineered for efficiency and flexibility, allowing for fast skin and colour changes with the adoption of special valves and multiple extruders. This feature not only enhances productivity but also enables manufacturers to meet the diverse needs of their customers with ease.

The implications of Tecnomatic’s innovative die-head extend far beyond the realm of microduct pipe production. By enabling faster, more efficient manufacturing processes, it paves the way for accelerated deployment of fiber optic networks worldwide. This, in turn, translates to improved connectivity, economic growth, and quality of life for millions of people around the globe.

As the demand for high-speed internet continues to rise, so too does the importance of robust and efficient infrastructure. With Tecnomatic’s groundbreaking die-head leading the way, the future of fiber optic connectivity has never looked brighter.