Your benefits at a glance

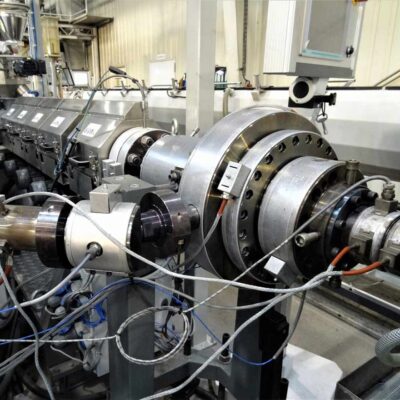

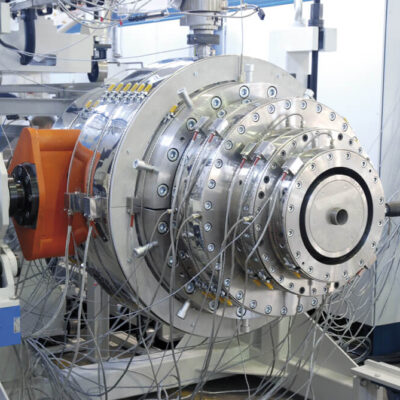

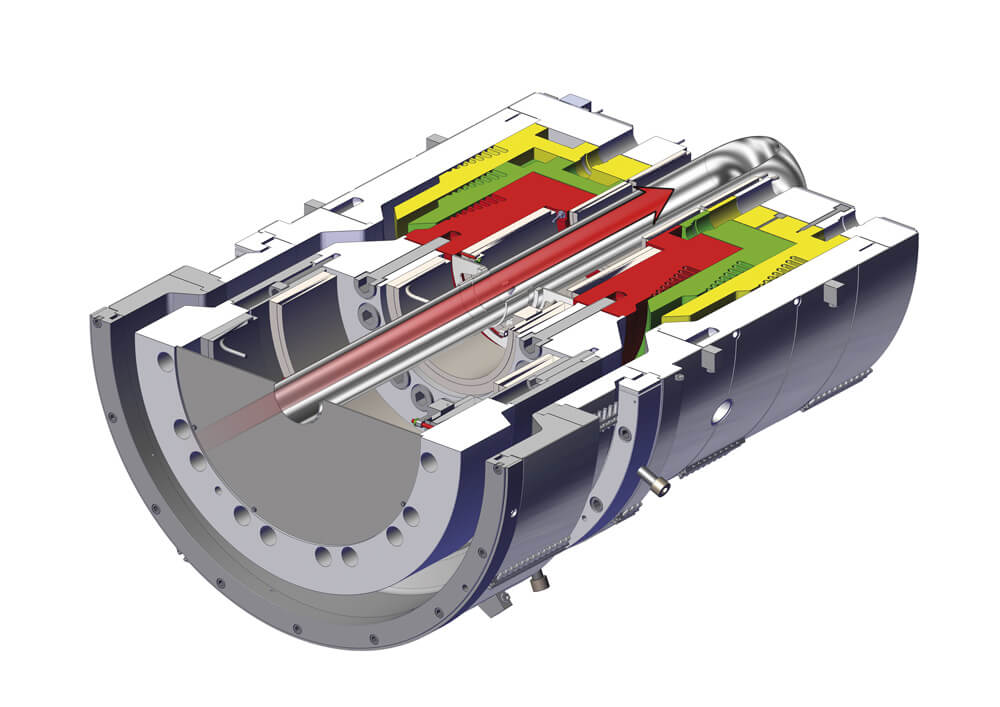

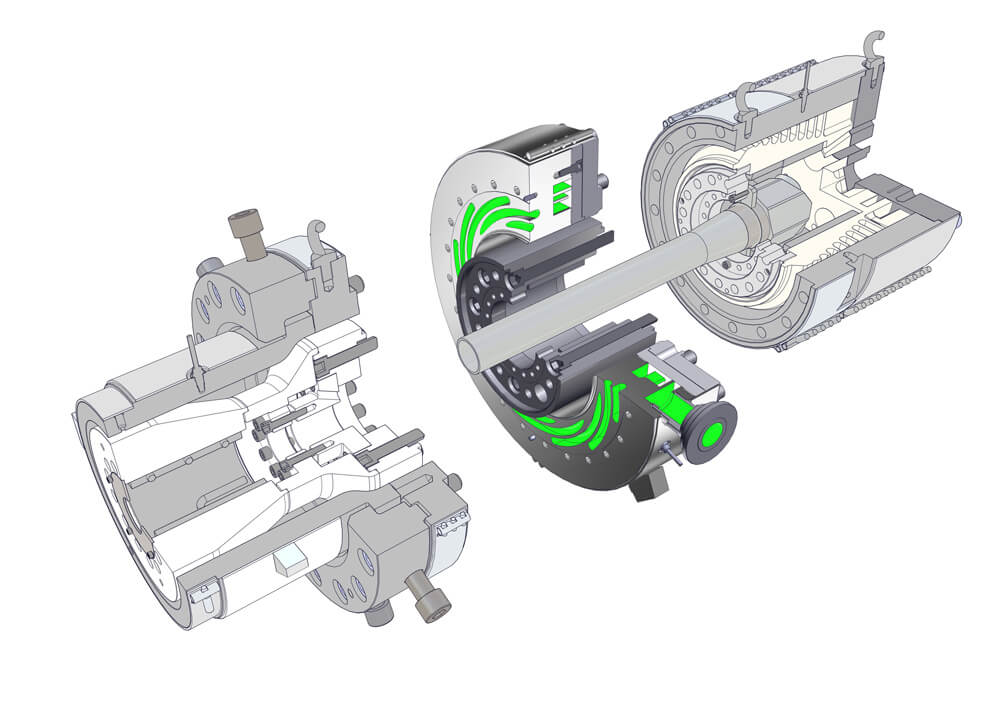

- The flows melting point is designed to adapt to a wide range of thickness-ratios.

- Smooth flowing to keep the material properties unchanged.

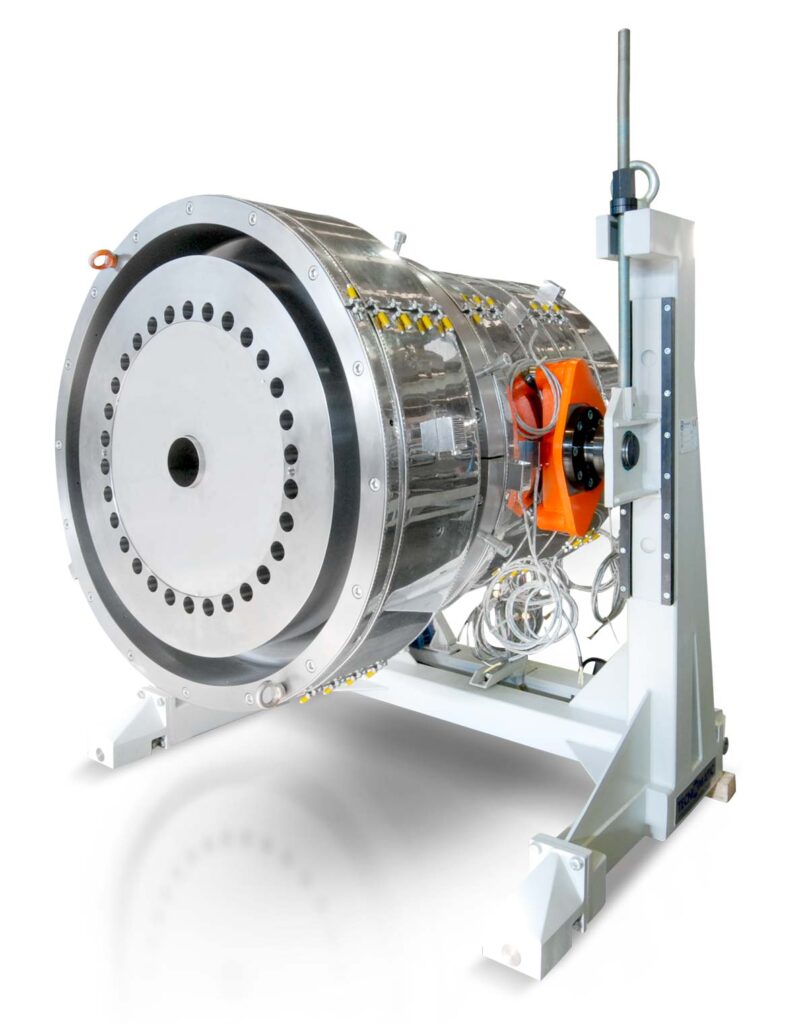

- Short die-set and segmented mandrels allow an easy and quick die-sets change,

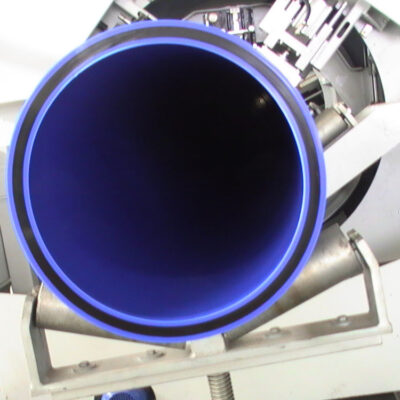

reducing the line downtime. - Even wall thickness distribution for lower overweight of pipe and raw material saving.

- Pipe Air Cooling (PAC) system to short the cooling and to improve the pipe quality.