TECNOMATIC PUSHES FOR SUSTAINABILITY DELIVERING A BRAND-NEW LINE TO PRODUCE REEL SUPPORT CORES FROM ARTIFICIAL GRASS SCRAPS

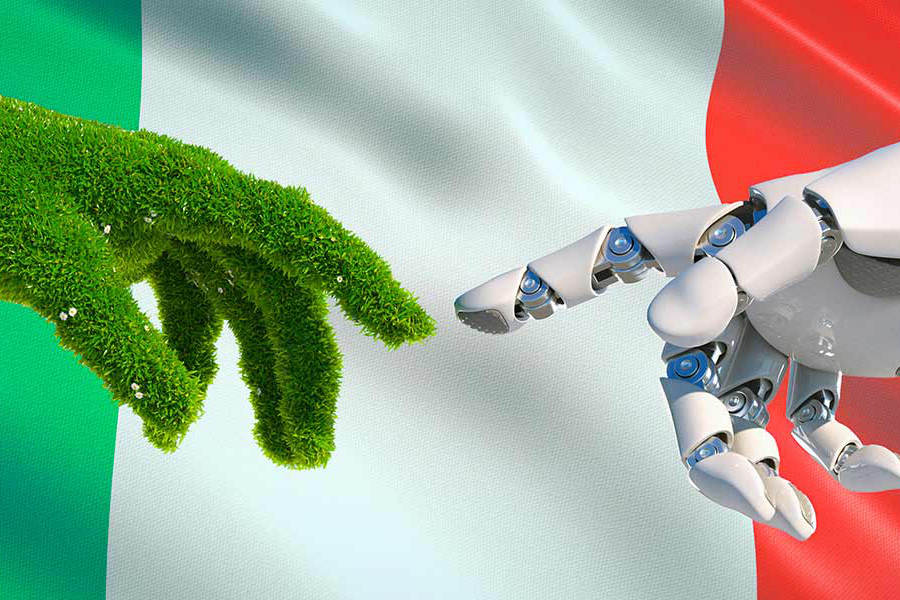

In an era where environmental concerns are at the forefront of global discussions, businesses are actively seeking sustainable solutions to reduce their ecological footprint. In a significant stride towards eco-friendliness, Tecnomatic, a leading machinery manufacturer, partnered with ITALGREEN, a prominent artificial grass company, to introduce a groundbreaking and sustainable production line for reel support cores. Italgreen is a trailblazing company in providing innovative and sustainable solutions in the artificial grass industry. Founded with a vision to revolutionize outdoor sports and landscapes, Italgreen has consistently combined cutting-edge technology with environmental consciousness, making it a leader in eco- friendly synthetic turf solutions.

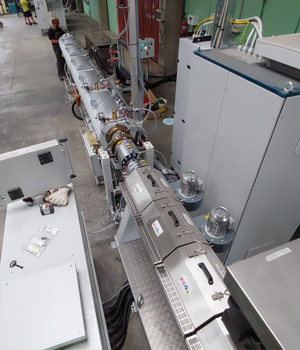

This innovative line effectively reuses scraps from artificial grass production, minimizing waste and promoting circularity in the manufacturing process. Central to this venture are Tecnomatic’s cutting-edge technologies, including the ATLAS series 75.30 extruder, anti- humidity volumetric dosing system, die- head VENUS 160, and downstream tanks, haul-off, cutter and tip table.

At the heart of this sustainable initiative lies Tecnomatic’s state-of-the-art ATLAS series 75.30 extruder. This high-performance extruder plays a pivotal role in processing the recycled scraps obtained from the artificial grass production process. By leveraging advanced technology and precision engineering, the extruder efficiently transforms the reclaimed materials into the raw material needed to produce reel support cores. This process significantly reduces the need for virgin raw materials, thereby conserving natural resources and lowering the overall environmental impact.

Consistency in material properties is essential to produce high-quality reel support cores. To ensure this, Tecnomatic incorporates an anti-humidity volumetric dosing system into the production line. This innovative system accurately measures and regulates the input of recycled materials, preventing any potential fluctuations in material properties due to moisture content.

The die-head VENUS 160 is a critical component of the production line, responsible for shaping the extruded material into the desired core dimensions. Tecnomatic’s die- head technology excels in providing precise control over the core’s diameter and thickness, ensuring consistency across the entire production process. Moreover, the die-head’s versatility allows for the production of various core sizes, up to 130 mm, to meet the needs of ITALGREEN’s core reel production.

The downstream tanks, haul-off, and cutter are instrumental in completing the manufacturing process. The downstream tanks facilitate cooling and solidification of the extruded material, while the haul-off system maintains tension and speed during production. Finally, the cutter efficiently cuts the cores to the desired length, resulting in ready-to-use components for ITALGREEN’s artificial grass rolls.

The partnership between Tecnomatic and ITALGREEN exemplifies a remarkable step towards sustainable manufacturing and circularity in the industry. By repurposing scraps from the production of artificial grass into reel support cores, this innovative production line significantly reduces waste and minimizes the demand for new raw materials.

In a world increasingly aware of environmental challenges, Tecnomatic’s commitment to eco-friendly solutions sets a standard for other industries to follow suit. The circular production of reel support cores for artificial grass not only showcases the potential for sustainable manufacturing but also highlights the importance of collaboration and technological advancement in achieving a greener future. As more businesses embrace circular economy practices, we move closer to a harmonious balance between economic growth and environmental preservation.