INNOVATIVE DIE-HEADS DESIGN BY TECNOMATIC FOR MULTILAYER PLASTIC PIPES WITH INNER LAYER IN PA OR PVDF FOR CHEMICAL AND GASEOUS MATERIAL TRANSPORT

Tecnomatic, a leading Italian company in the field of extrusion technologies, has recently introduced new die-heads for multilayer plastic pipes with inner layer in PA for hydrogen transport or inner protective layers in PVDF. The new die-heads are the result of the company’s new R&I team’s efforts to develop innovative solutions that meet the growing demand for safe and reliable transport of hydrogen and other chemical products.

Hydrogen is increasingly seen as a clean and efficient energy carrier that can contribute to the reduction of carbon emissions and mitigating climate change. However, the hydrogen transportation poses significant challenges, as it requires special materials and technologies that can ensure its safe handling and delivery. Tecnomatic’s new die-heads for multilayer plastic pipes with inner layer in PA are specifically designed to face these challenges.

The use of PAs (polyamides) as an inner layer provides high resistance to hydrogen permeation and excellent mechanical properties. PA is a thermoplastic material that has high tensile strength, high elastic modulus, and excellent impact resistance. It is also resistant to many chemicals, including hydrocarbons and alcohols, making it suitable for use in the transport of fuels and other chemical products.

The outer layers of the multilayer pipes are made of PE, while an inner layer of PVDF (polyvinylidene fluoride), a highly resistant and chemically inert material provides excellent protection against corrosion and chemical attack. PVDF is widely used in the chemical process industry for handling harsh and unique liquids to gaseous products including sulfuric, nitric, and hydrochloric acid, as well as compounds such as halogenated, aliphatic, and aromatic solvents. It is also used for handling natural and refined products, oils, and combustible fuels.

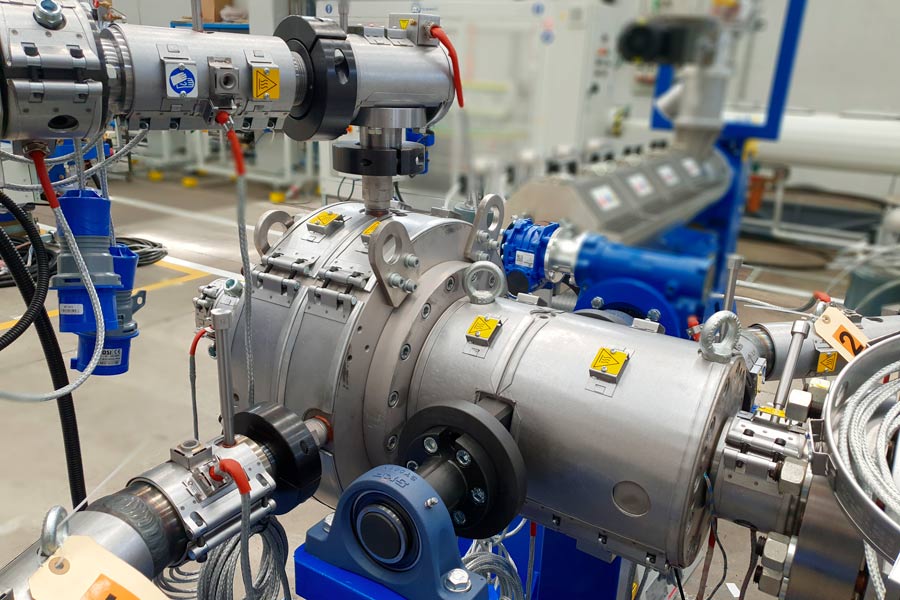

Tecnomatic’s die-heads are designed with a meticulous attention to detail, considering not just the mechanical performance, but also the specific characteristics of the polymers being processed. For polyamide (PA) and polyvinylidene fluoride (PVDF), Tecnomatic uses materials and treatments that are specifically tailored to meet the unique demands of these materials. This ensures that the die-heads can achieve optimal processing efficiency while minimizing any potential material degradation. With Tecnomatic’s die-heads, you can be confident that your PA and PVDF processing needs are being met with the utmost care and precision.